About Us

|

|

|

|

|

Early Years

Kinion Dunn, founder of DBT, was living with his wife Barbara Dunn raising four sons in their hometown of Cookeville TN. He worked as an engineer for a local automotive manufacturer, FleetGuard. After leaving FleetGuard he began his own engineering design business in 1989, this business became the framework and precursor to DBT. Through the next few years, he worked with local companies designing components and machinery, for the automotive industry.

|

|

|

|

Business Open

|

|

|

|

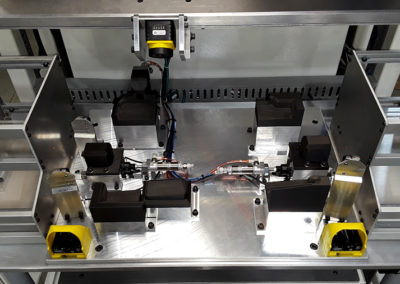

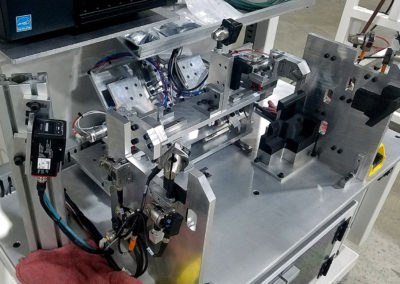

Growth and Production

In 2001, DBT was growing and expanding so fast, it quickly realized that additional production and fabrication spaces would be required. Through the efforts of Kinion, and his family, DBT had outgrown their current manufacturing space. This led to the addition of 3,720 square feet, allowing DBT the space to build larger machines and keep up with customer production needs. During this period, DBT added CNC milling and lathe capabilities. Along with the technological upgrades, DBT added its business division FXC (FluidXChange). FXC services the trucking industry, helping cut preventative maintenance time and streamlining maintenance practices.

|

|

|

|

Growth and Engineering

With the unprecedented growth of both DBT and FXC, it was soon realized that additional engineering and office spaces would be needed. In 2005 a second expansion was started. This one added 1,800 square feet to the already existing engineering, design, and office spaces. This was critical due to the increased engineering and design demand created by earlier expansion and growth. Throughout the next fifteen years, Kinion worked to mentor and train his engineering, manufacturing, and fabrication staff. They are a 9001:2015 quality system registered facility, which ensures their productions have a high standard. These efforts created a true “family” environment that produces high quality products for their customers. DBT values its employees as if they were part of the Dunn family. Each person is a critical part of the team and adds to our incredible effectiveness.

|

|

|

|

Present

Today DBT strives to bring superior customer service along with top-notch engineering and design capabilities. Through the use of CNC, 3D printing, and advanced machining technologies DBT is able to reach new customers and markets. Through our family values, loyalty, integrity, and service, we are able to create our success. Through the positive impact on our community and the people around us we are able to measure our success. By providing opportunity to our community, our customers, and our families Kinion has enabled DBT to continue its growth. Our motto: “Taking your manufacturing needs from concept to completion”, remains a strong focal point. We are proud to continue serving our customers and community for many years to come.

Location

635 Industrial Drive

Sparta, TN 38583

Hours

Mon. thru Fri. - 8am - 4pm

Sat. / Sun. - Closed